What Is the Purpose of an Airsoft Wire Channel

What Is the Purpose of an Airsoft Wire Channel

Airsoft Gun Wiring Repairs

Airsoft gun wiring plays a very important function in the optimal functionality of all automatic AEGs. Currently, some models come packed with beautifully intricate electronic Mosfets and triggers. Yet, today, what I'll exist addressing is the general wiring of an Airsoft AEG and the associated components. These include:

- Fuses

- Battery connections

- Motor connections

- Standard trigger contact shuttle and the complete contact system

- The AEG wiring that completes the circuit

Fuses

When y'all get to the electrical circuit of an AEG, yous are going to find some sort of fuse link and a fuse holder. In full general, Airsoft factories utilise fifteen amp fuses in social club to protect the circuit of the motor. In example your motor fails when you burn down the trigger, the commencement diagnostic step is checking your bombardment and fuse connection. In example yous upgraded your gun for a higher FPS with high torque motors, you may have had to take the fuses out for ideal functioning. Notwithstanding, if you lot use them or you lot are a piffling concerned most your setup, here are 2 great options for you.

- Plastic or glass automotive fuse : yous will find them in the majority of stock AEGs out there. In instance they trip, you merely supercede it by popping another one in.

Effigy : AEG Plastic blade type fuse

Source: havarhen , Electrical fuses, plug-in type, unlike sizes , CC BY-SA 3.0

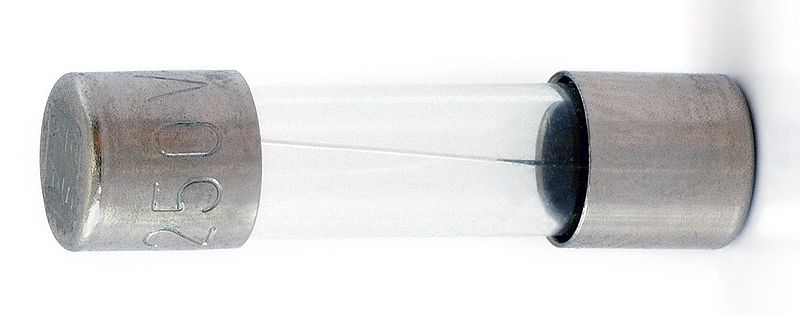

Figure : Glass fuse

Source: Aka , Glassikring , CC BY-SA ii.5

- Resettable/Polyfuses: when heated, these types expand gradually to such a point that they can't behave electricity any more. Afterward the circuit is broken and electric current is no longer flowing, they cool and contract to a point where they can conduct current once once again. Notwithstanding, after they trip for the first time, they hands trip again unless you requite them enough cooling fourth dimension.

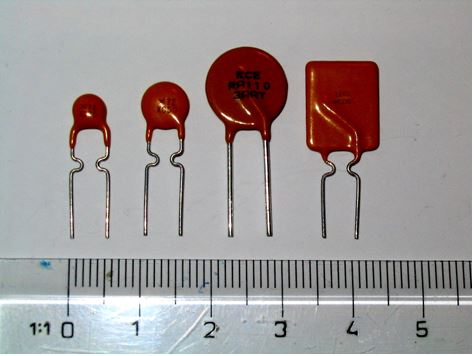

Figure : Resettable Polyfuse

Source: By Shaddack (Own work) [Public domain], via Wikimedia Commons

Connections

- Battery Connections

In electric Airsoft guns, the connections essentially begin at the battery, located on the butt stock or at the forepart grip, depending on your model. There are 2 main battery connections that are used depending on your gun's model. They are:

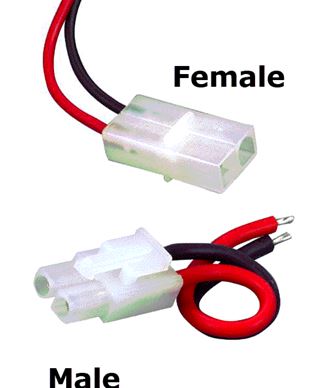

- Pin/Tamiya plug connector – Accept lighter contacts with lower amperage rating. These are much more susceptible to loosen up and will likely pb to recurrent repairs since they article of clothing out after roughly 50 cycles.

Figure : Tamiya Plug Connector

Source: By Blackeagle2001 at English Wikipedia [Public domain], via Wikimedia Commons

- T-Blazon/Deans plug connectors – The contacts are much heavier since they have a higher amperage rating of between thirty-twoscore amps. This translates to less resistance and thus, a cooler running motor

Figure T-Type/Deans Connector:

Source: KundaliniZero , Deans connector 1 , CC BY-SA iii.0

How to add the T-Type/Deans plug connectors

If y'all are tired of the recurrent repairs of the Pivot/Tamiya plug connector, here is how you tin replace them with the much improve T-Type/Deans plug connectors.

Technical Outline

- OBJECTIVE: Calculation the T-Type/Deans plug connectors

- DIFFICULTY LEVEL (on a scale of 1-10): half dozen

- DURATION: 20-30 minutes

Required Tools

- Soldering iron

- Flux

- Sandpaper

- Heat compress tubing

- Wire Strippers

- Pliers

Required Replacement Parts

- T-Type/Deans plug connectors

Figure T-Blazon/Deans Connector

Source: .HYPERLINK "https://commons.wikimedia.org/wiki/User:.tirnado"tirnado , T-plug , CC BY-SA three.0

Procedure

STEP A:

Cutting off the Tamiya Plug connectors. In case this is the battery, ensure that you lot only cut off a single pb at a fourth dimension and so that y'all can avoid a short excursion. You can as well employ a clip or vice to clench the Deans plug to concur it as you lot solder. In about cases, the male person end is continued to the AEG harness and the female end goes to the battery.

Step B:

Next, ready in each of the terminals of the Deans plug by adding a solder chimera to each of the tabs of the terminal

STEP C:

From there, identify a heat shrink piece on each of the wires that are to be soldered and join the positive (+) wire to the perpendicular tab and join the negative wire to the flat tab.

- Motor Connections

Moving to the mitt grip, you lot will find the motor and its wire terminals which connect it (the motor) to the wire harness. Sometimes due to vibrations, these terminals may end up getting lose from the motor, causing a short circuit that causes motor failure. To foreclose these shorts, the gun motor terminals should exist tightly fitted and properly insulated. At that place are iii main options for motor connectors:

- Standard Motor Connectors: have very high resistance and thus, they aren't the best choices.

- Golden Plated Motor Connectors: these allow for increased contact between the connector and the tab of the motor and thus the resistance reduces significantly.

- Directly Soldered Connectors: the wire is directly soldered to the motor tab. These are the best options especially since the resistance is minimal. Nonetheless, every fourth dimension you remove the motor, you lot take to de-solder them.

Trigger Contact Shuttle and the Contact System

When you go inside the gearbox you will find the contact shuttle and the trigger contacts. Only the red (+) wire should be continued across the switch. In older AEG circuits, the selector plate is used equally a point of contact too. When running maintenance of your electrical gun, check the contact assembly'south return spring and clean the contact surfaces in case they have a noticeable carbon build upwards or whatsoever other visible kind of dirt. DO Not scratch the contacts. Check for whatsoever pitting or called-for and you tin can replace if demand be. In case you program on upgrading your AEG for heavy use situations or higher FPS, use higher temperature contacts and shuttle.

AEG Wire Pick

There is a vast choice of wires that you lot should consider using in your AEG depending on the advantages and disadvantages. Here's a quick breakdown:

Solid Wire

Pros:

- Very thin

- Has low resistance

- Can handle college amperage than an equivalent gauge stranded wire

- Very potent and can easily be routed through the gearbox

Cons:

- Fragile

- Might be too stiff in some cases

Silicone Wire (Deans Wet Noodle)

Pros:

- Exceptionally depression resistance

- Highly flexible

Cons:

- Pretty expensive

- Quite thick

- Tough to solder

- Its insulation tears hands

Hook-upwardly Wire

Pros:

- Highly flexible

- Thinner than a regular silicone wire

- It'due south very affordable and easy to find

- Pretty tough insulation

Cons:

- Its 16-estimate wire may sometimes be too thick for the V2 gearbox

- Its operation in depression resistance and amperage is not sufficient

Teflon Coated Mil-spec Wire

This is the standard OEM wire in Tokyo Marui, Prometheus and Systema

Pros:

- Pretty potent insulation

- Uncommonly thin: a 16AWG Teflon wire is much thinner than whatever other kind of AEG wire

- Comes with a silver coated copper conductor

- Low resistance

- Quite strong and can easily be routed through AEG bodies and gearboxes

Cons:

- Costly

- Not very forgiving in case you wrongly mensurate out the lengths

Wire Size

Wires are measured in the AWG (American Wire Judge) system where the gauge number is inversely proportional to the size of wire. i.e. the larger the number, the smaller the wire. Basically, the size of the CONDUCTOR is the but aspect that determines the gauge and non the wire's overall size.

Depending on the manufacturer of the Airsoft gun, the wires used may exist PVC or silicone coated and in general, a 16 AWG wire is used and information technology can handle 75 amps. Notwithstanding, high finish companies typically go for heavier 14 AWG wires while low end companies use xviii AWG wires which are lighter. In the USA, depression resistance PVC coated wires are readily bachelor and silicon wires can even be bought from hobby shops.

For the best performance of your Airsoft gun, the type of battery and voltage also play a crucial role, but that is a topic we'll comprehend much deeper another day.

Pace by Stride Guide on How to Replace a Version 2(V2) Wiring Harness

Does it feel like your AEG starts having problems right when y'all are in the rut of the action? Well, in such a situation, what do yous do? Instead of shifting your focus in some rather unfulfilling activities like binge watching a Television bear witness, I will show y'all how can go your AEG upwards and running again in less than an hour. Whether you are having a serious mechanical trouble or you are merely looking to requite it an interior upgrade, you will find this guide quite useful.

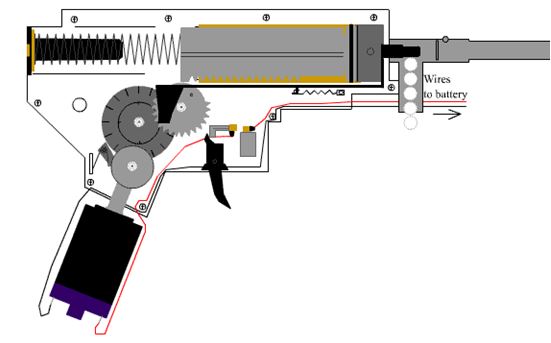

Figure : How a Version 2 Electric Motor Gearbox Works

Source: Past Ranger Helm at English Wikipedia Afterward versions were uploaded by Boffy b at en.wikipedia. (Transferred from en.wikipedia to Commons.) [Public domain], via Wikimedia Commons

The process of diagnosing a harness problem may end upwards being quite difficult and for that reason, we'll offset by highlighting a couple of issues on a diagnostics checklist. So, if you have a damaged switch assembly, it could lead to issues such as;

- losses in the semi-automatic firing,

- an excessively long pull of the trigger, a delinquent gun

- no firing at all.

If you experience any of the above problems, here are a couple of things you should do earlier annihilation else:

- Check the fuse and ensure that information technology is yet intact and it works properly

- Confirm that the battery is fully charged

- Next, counter-check whatsoever of the gun'due south connections. For instance, the motor connection. In some guns, an inline connector is placed in the wires for easier and faster dismantling either in the fore grip or stock.

- If everything else is right and things signal to the AEG wire harness, you should merely become information technology out; and the wire harness is what we'll comprehensively embrace in this dossier.

Here, we are going to accept the V2 gearbox autonomously, identify the problems, fix them and put information technology back together. Since at that place are a wide range of ways in which each gun can be disassembled, let's simply jump right to the part of dismantling the gearbox. Permit's get right to it!

Technical Outline

- OBJECTIVE: To Replace the Wire Harness of an AEG

- DIFFICULTY LEVEL (on a scale of ane-10): vi

- Duration: twoscore-50 minutes

Required Tools

- Flat caput screwdriver

- P2 Phillips screwdriver (large)

- P1 Phillips screwdriver (pocket-size)

- 2mm hex for sliding into the jump guide when stabilizing the gearbox

Required Replacement Parts

- Wiring harness and V2 Plunger

- Raptors Airsoft DeepFire Switch Assembly

Procedure:

Stride A:

Kickoff past taking off the bolt catch in case there is one. On this detail VFC gearbox, there is a bolt catch. Use the P1 screwdriver to dismantle it from its retaining spiral. Be very cracking so that you don't lose the tiny spring that lies below. Only after that, undo all the other gearbox trounce screws with the large screwdriver. Other gearbox brands may have 2mm Torx or hex type screws.

STEP B:

Detach the halves of the gearbox then take out the internal components. To forbid the spring guide from flying out, place a 2mm hex wrench through it and then take off the top half of the gearbox using your other gratis mitt. Place it aside then take the spring out slowly. After doing that, take out the piston, nozzle of the cylinder and the tappet all in one slice. Be conscientious not to lose the spring of the tappet. Remove the airsoftgears while staying on high alert to proceed the gear shims in their proper place. Afterward that, disassemble the AR (anti-reversal) latch and the spring.

STEP C:

Here comes the most interesting part; identifying the trouble. Some of the things you should keep an center out for in terms of damage include:

- The two contumely tabs on your plunger assembly could be bent apart and thus not making proper contact with the plunger (the small movable function) itself

- The tabs could be fried completely

- Cleaved return jump on the upper section of the unit of measurement

- The tiny notch on the back side may be mashed up from the cut-off lever, thus preventing semi-auto

Pace D:

If you are lucky, you could shorten the pull on the trigger simply by pushing the two brass tabs slightly closer to each other to brand the circuit close sooner. However, exist careful not to overdo it since it could lock the plunger in place leading to much longer fires than ideal. On the other hand, in case the unit is in a poor condition, melted or completely fried, you lot will be better off when yous replace it. If your wiring is still in great condition, but change this area by soldering out the former unit of measurement, gear up the new unit in and solder it back to the wires.

Footstep E:

In case you are replacing the new wires and wiring harness, make sure that you lot properly insert the wires in the gearbox. The wire that crosses the gap close to the motor should be kept beneath all the other wires. In improver, be sure to push the wires deep enough into the grooves when yous gear up them but take circumspection so that yous don't strip them or impairment them in any other way. If you lot harm them in that procedure, it could lead to a agglomeration of other problems such as dissentious the new harness, your battery or even worse, the gun could grab fire on its own!

STEP F:

Confirm that you have secured all the parts properly and the leads of the motor are placed where they should be. The red wire should be at the front while the black wire is supposed to exist at the back. Yous should as well brand sure that the right connector is also in place, whether you lot use Deans or Tamiya.

Step G:

After everything is in identify, reassemble the gearbox component and screw it up. Ensure that you align every component properly and that the shims are in their proper identify. Gently tighten up the screws of the gearbox equally well as the bolt grab.

STEP H:

To test the gearbox wiring, adhere the power wires to the battery and then connect the other cease to the motor. To prevent the pinion gear from hitting stuff, hold the motor in place. Fire upward the trigger and if the motor turns over, then everything is right, you tin can go on with the associates. In case the motor doesn't plow over, counter-check all the connections and check to ensure that the plunger is able to slide at will in and out of the tabs of the trigger. If everything else checks out afterwards that, continue re-assembling the remaining components of your AEG and you tin can hit the field again whenever you want.

Extra AEG Tips for Boosting Operation:

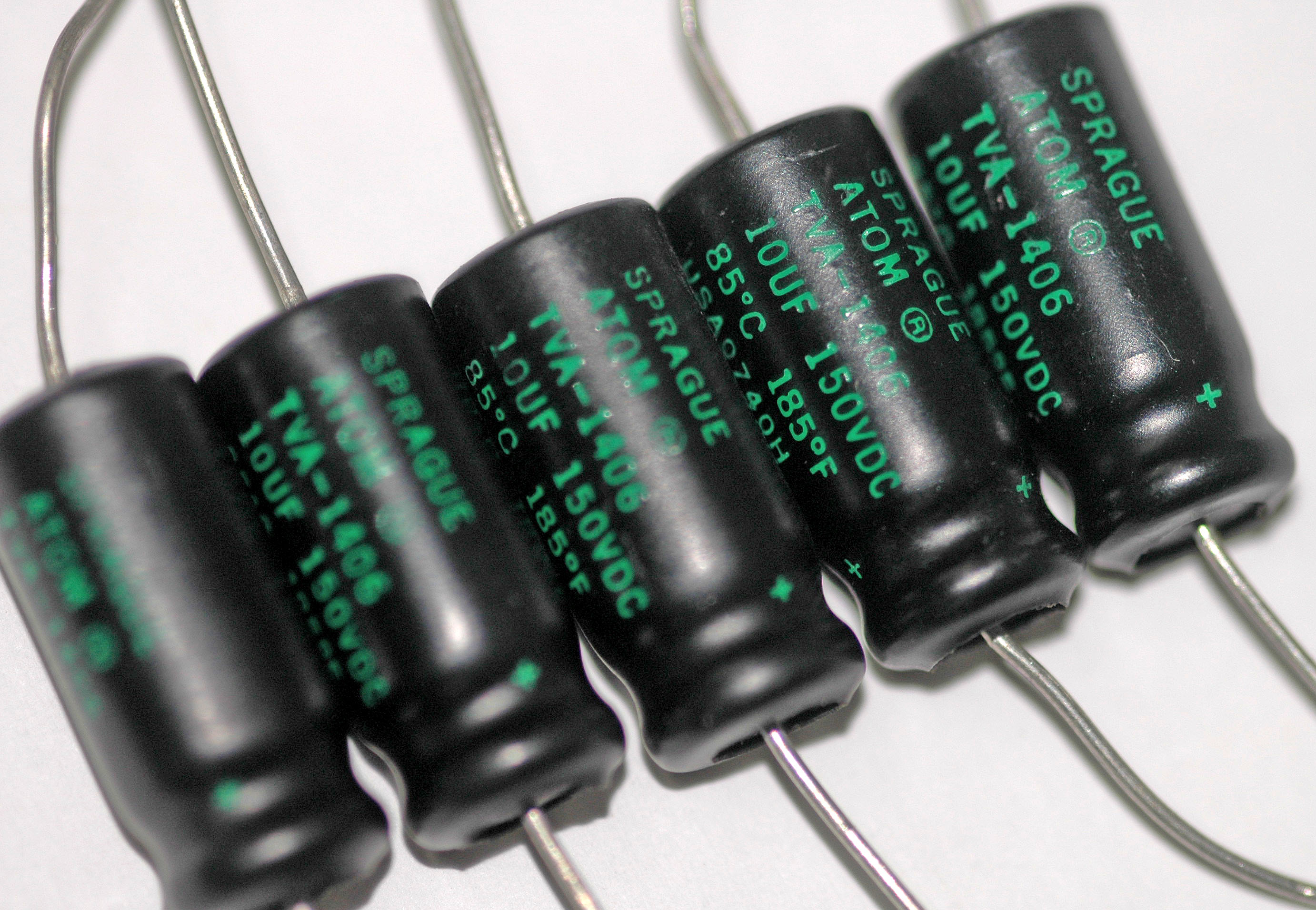

- Capacitor Banks

I of the all-time ways of boosting your rate of burn and trigger response, is by use of Capacitor Banks. Electrolytic capacitors are essential in the storage of free energy and releasing in on need. This is what volition conform for the voltage drops that occur correct after your initial pull of the trigger and when the AEG cycles through shots.

Figure : Axial Electrolytic Capacitors

Source: Mataresephotos , Centric electrolytic capacitors , CC BY 3.0

During the voltage drops, the capacitor volition release its stored energy and thus smooth out the current. Later on the voltage drib passes, the capacitor will make full upwards again. Nonetheless, the improvement is rather minimal and for a significant divergence and y'all are going to need a pretty huge bank. You lot should all the same annotation that not all AEGs will have enough room for this actress fitting. If you have enough room to fit them in, there are virtually no downsides in using them.

How to Install a Capacitor Bank

Installation is quite simple, here is what you lot should exercise:

Step A:

Find a suitable location for them.

Step B:

Start soldering them in parallel connection to the circuit of your AEG wire system

Stride C:

Since the capacitors are polarised, make sure you get the polarities right. If yous aren't sure, yous can tell the negative (-) terminal by confirming that it has a stripe that runs downwardly the cap on one side.

NOTE: Make your capacitor banks removable then that you can hands switch them from i gun to another.

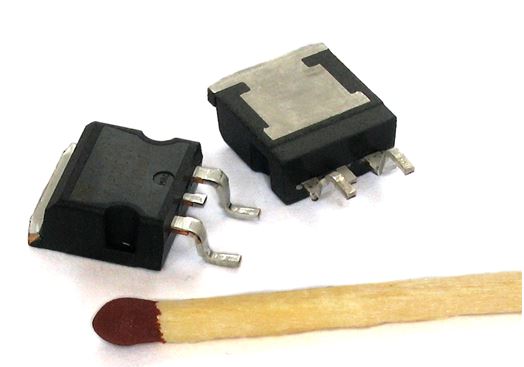

- Mosfets

In AEGs, a mosfet is a switching transistor capable of treatment loftier loads and transmits exceptionally low internal resistance. Some of the main benefits of mosfets include:

- Boost ROF

- Provides allowance for the utilise of batteries with higher voltages

- Prevents called-for up of trigger contacts

- Enhance trigger response

- Powers up your electrical system'southward overall efficiency

With some soldering skills, it is quite piece of cake to brand a Mosfet unit. Here'southward how yous can do it in like shooting fish in a barrel steps.

Figure : MOSFET

Attribution: CyrilB~commonswiki causeless (based on copyright claims)., D2PAK , CC BY-SA 3.0

How To Brand and Add A Mosfet Unit of measurement

Technical Outline

- OBJECTIVE: To Make and add together a Mosfet Unit to an AEG

- DIFFICULTY LEVEL (on a calibration of i-x): seven

- Elapsing: 50 minutes – ane hr

Required Tools

- Soldering iron

- Flux

- Sandpaper

- Heat shrink tubing (in various sizes)

- Wires (for the motor and gate) and Wire Strippers

- Voltmeter

- Glue Gun

- Heat Gun

- Helping Paw Tool

- Pliers

- Wet Cellulose Sponge

Required Parts

- 2 100Ω resistors

- Two 20-30kΩ resistors (pull-down resistors)

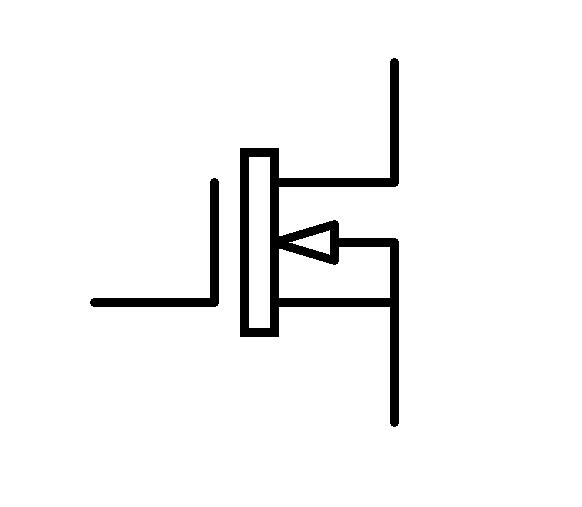

- A Suitable N-Channel Mosfet (ideally IRL1404z)

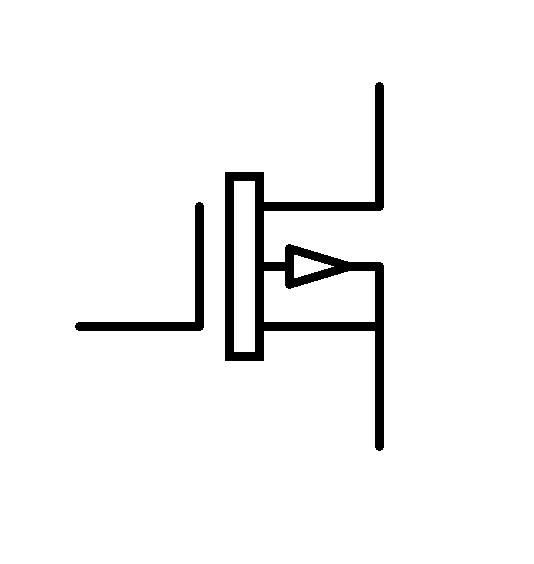

- Northward-aqueduct and P-channel Mosfet (for AB system)

Figure : Resistor

Source: Nunikasi , Resistor , CC BY-SA 3.0

Figure : N-Channel Mosfet

Source: Marvelshine , MosfetHYPERLINK "https://commons.wikimedia.org/wiki/File:Mosfet_n.JPG" n , CC Past-SA iv.0

Effigy : P-Channel Mosfet

Source: Marvelshine , MosfetHYPERLINK "https://eatables.wikimedia.org/wiki/File:Mosfet_p.JPG" p , CC BY-SA 4.0

Procedure

Pace A:

Cover the Mosfets heatsink with heat-shrink tubing to forestall shorting annihilation just by touching it since the heatsink and the Drain pin contain an equivalent electric value. Add some rut-shrink tubing to the pull-downward resistor as well.

STEP B:

The Mosfet has iii pins, the Gate, the Drain and the Source. Join the insulated pull-down resistor between the Gate pin and the Source pivot and then attach the 100Ω resistor to the gate pin.

Step C:

De-solder each of the trigger contacts then attach a gate wire (yous can use the tiny wires found in an Ethernet cable) to each of the contact tabs.

STEP D:

From there, add new wires directly from the battery all the way to the motor. Don't forget to use heat-compress tubing every bit well.

STEP East:

Find a spot to put the Mosfet unit then clip the negative wire into two halves. Accept the half running to the motor and attach it to the Drain pivot of the Mosfet. From at that place attach the other half of the negative wire (which goes all the way to the battery) to the Source pivot of the Mosfet. Lastly, join one gate wire to the Mosfet's gate resistor and so connect the other gate wire someplace into the positive (+) wire. Your Mosfet system is complete!

Note: Before you forget, you should also include active breaking (AB) then that the motor stops the moment you release the trigger. Apart from creating a super-crispy trigger pull, active braking helps in keeping the piston frontward to prevent exerting unnecessary stress on the gears for instance. And so, to add active breaking, you should connect a P-channel mosfet. There are so many way of doing this and 1 of the simplest ways is as indicated in the steps that follow.

Step F:

Join the N and P-Aqueduct Mosftets by gluing them together back to back and then bend the Gate pivot of the P-channel to see up with the Gate pin of the N-channel. Bend both Drain pins (centre pins) of the Northward and P-Channel Mosfets together then join them with a quick solder.

Stride G:

As usual, kickoff by adding some estrus-shrink tubing to a pull-downward resistor and then add information technology between the Gate pin of the North-aqueduct and its Source Pin. Again, only like in your main Mosfet Unit of measurement, add the 100Ω resistor to the Gate pin of the N-channel mosfet. Finally, merely wire this active braking the aforementioned way y'all did in your main Mosfet unit; the but divergence being that the Source pin of the P-aqueduct is the ane that you should bring together to the positive wire.

You are now skilful to become with your powered-up artillery!

What Is the Purpose of an Airsoft Wire Channel

Posted by: colemanlauchime1996.blogspot.com

0 Response to "What Is the Purpose of an Airsoft Wire Channel"

Post a Comment